Corrosion related mot failure?

In 2024, approximately 25% of over 40 million MOT tests conducted in Great Britain resulted in failure. The most common failure categories included axles, wheels, tyres, suspension, and corrosion.

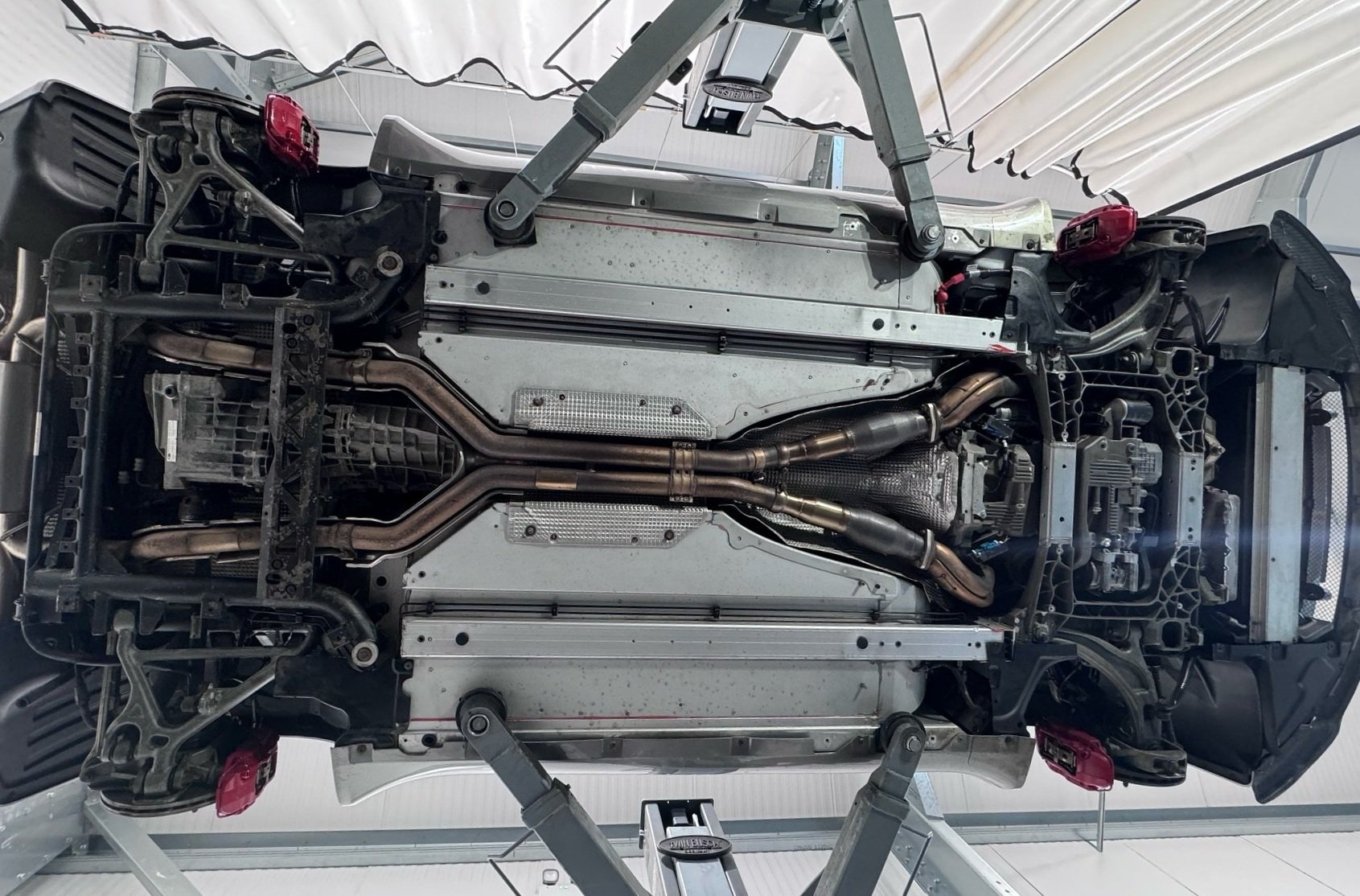

Corrosion can lead to failures or advisories in several MOT categories, particularly in structural components and braking systems. For instance, issues like excessive corrosion of suspension components, rear sub frames or brake pipes will likely result in MOT failures.

Rustproofing your car can play a crucial role in addressing corrosion and improving your chances of passing an MOT successfully. Corrosion, particularly in areas like the underbody, suspension components, brake lines, and chassis, is a common reason for MOT failures. When rust takes hold, it can weaken critical parts of the vehicle, making it unsafe and non-compliant with MOT standards.

By applying a protective rustproofing treatment, you create a barrier that shields vulnerable areas from moisture, road salts, grime, and other corrosive elements that contribute to rust. This preventative measure significantly slows down the corrosion process, helping to preserve the structural integrity and safety of your vehicle.

For vehicles that have already developed corrosion, rustproofing can be an effective way to treat affected areas after remediation, such as the removal of rust or application of rust inhibitors. This gives your car the best chance of passing an MOT, as it ensures the components are free from excessive corrosion and are functioning safely and effectively.

In essence, rustproofing acts as both a preventive and restorative solution, protecting your car from the long-term damage of corrosion and helping to maintain MOT compliance.